Phospholipid Quality Supplier,Amount Used to Produce Candy

Time:2024-12-02

Phospholipids play an important role in candy production, primarily serving as emulsifiers, stabilizers, and flavor protectants. Below is a detailed analysis of the control of phospholipid usage and key considerations in candy production:

Ⅰ.Control of Phospholipid Usage in Candy Production

1. Specific Usage Amounts

The amount of phospholipids added to candies varies depending on the type of candy and the desired effect. For example:

·In candies containing nuts and honey, the typical addition of phospholipids is about 0.5% to prevent oil and liquid seepage.

·In chocolate, phospholipid content generally ranges from 0.2% to 0.3% to help maintain shape, lubricate, and prevent the bloom effect caused by sugar crystallization.

·In some candies, such as cream-based candies, adding 0.5% phospholipids helps prevent oil seepage and improves mouthfeel.

2. Importance of Control

The amount of phospholipids used significantly affects the texture, mouthfeel, and stability of the candy. If the amount is too small, the emulsification effect may be poor, impacting the texture and mouthfeel of the candy. On the other hand, using too much may increase costs and even negatively affect the candy's quality.

Ⅱ.Key Considerations for Using Phospholipids in Candy Production

1. Choosing the Right Type of Phospholipid

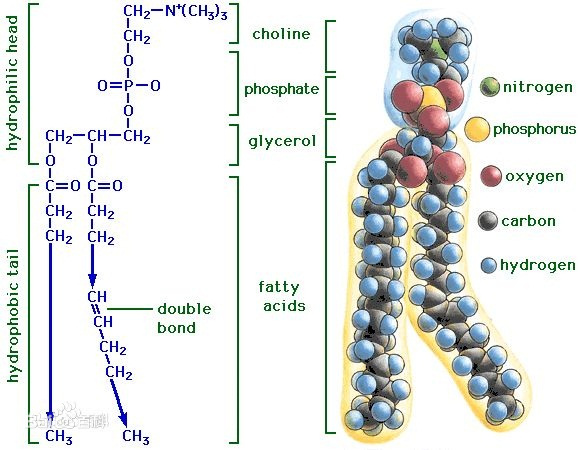

It is important to select the appropriate type of phospholipid based on the type of candy and the desired effect. For candies requiring improved emulsification, hydrophilic phospholipids are preferred. For candies that need to prevent oil or liquid seepage, phospholipids with better water-repellent properties should be chosen.

2. Timing of Phospholipid Addition

The timing of phospholipid addition plays a crucial role in the production process. In chocolate production, phospholipids should be added towards the end of the refining process during the liquid-phase refining stage to ensure they function effectively. In other candy production, the addition timing should be determined according to the specific production process and recipe requirements.

3. Uniform Mixing of Phospholipids

Phospholipids should be evenly mixed with other ingredients to ensure they are distributed uniformly throughout the candy, thus achieving optimal performance. This typically requires thorough stirring and dispersion during the mixing process.

4. Storage and Transportation of Phospholipids

Phospholipids should be stored and transported in a dry, cool, and ventilated environment, away from direct sunlight and high temperatures. It is important to prevent contact with moisture or oxidizing agents to avoid compromising their quality and effectiveness.

5. Compliance with Relevant Regulations and Standards

The use of phospholipids in candy production must comply with relevant regulations and standards to ensure product compliance and safety. This includes adhering to limits on the amount of phospholipid, its approved usage range, and compatibility with other ingredients.

The control of phospholipid usage and the consideration of key factors in candy production are essential to ensuring the quality and safety of the final product. In practical production, the appropriate type of phospholipid, addition timing, and mixing method should be chosen based on the candy type and desired effect. Furthermore, relevant regulations and standards must be strictly followed.

CN

CN