Food Grade Phospholipid Supplier,Safe Source

Time:2024-11-27

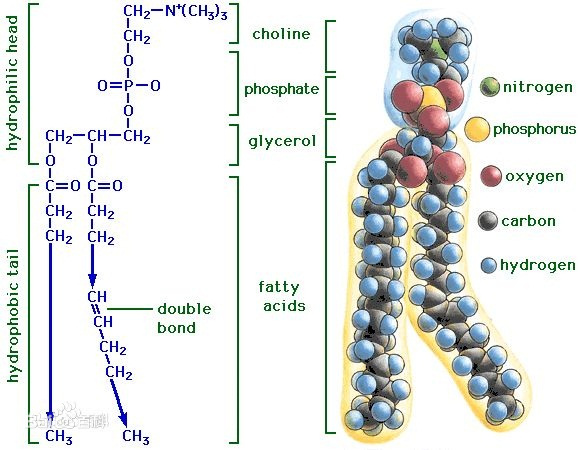

Food-grade phospholipids are a vital class of food additives with diverse sources and significant attention to their safety. Below is a detailed analysis of the sources and safety evaluation of food-grade phospholipids:

I. Sources of Food-Grade Phospholipids

1. Soy Lecithin

·Soy lecithin is one of the most common sources of phospholipids, extracted and separated from soybeans.

·It is widely used in food processing industries, including dairy products, baked goods, oil-based products, and meat products.

2. Egg Lecithin

·Egg lecithin is derived from eggs and is rich in phosphatidylcholine and other lipid components.

·It is commonly used in various food products, such as egg-based items, pastries, bread, and seasonings.

3. Fish Lecithin

·Fish lecithin is extracted from fish and contains beneficial components like omega-3 fatty acids and phosphatidylcholine.

·It is often used in fish oil supplements, health foods, and dietary products to provide nutrition and support cardiovascular health.

4. Plant Oil Lecithin

·In addition to soy lecithin, other plant oils, such as sunflower seed oil, peanut oil, and corn oil, can also provide phospholipids.

·These plant-based lecithins are used in various food products, such as seasonings, oil-based products, and baked goods.

5. Other Sources

·Phospholipids can also be extracted from other materials, such as flaxseed, dairy products, and meat.

·These sources may be utilized in specific food products as needed.

II. Safety Evaluation of Food-Grade Phospholipids

1. Extraction and Production Processes

·The extraction and production processes for phospholipids must be strictly controlled to ensure product quality and safety.

·Factors such as the solvents, temperature, and time used during extraction can influence the quality and safety of phospholipids.

·Production processes must adhere to Good Manufacturing Practices (GMP) and quality control standards to ensure product purity and stability.

2. Testing and Certification

·A series of tests is essential to ensure the safety of phospholipids.

·These tests assess physical properties, chemical composition, nutritional content, and harmful substances.

·Common testing items include:

·Physical properties: Appearance and odor checks, solubility tests.

·Chemical composition: Phosphorus content, acid value, peroxide value, iodine value.

·Nutritional components: Phosphatidylcholine (PC), phosphatidylethanolamine (PE), and phosphatidylinositol (PI) content.

·Safety indicators: Heavy metal content, pesticide residues, solvent residues, and microbial contamination.

·These tests ensure that phospholipid products comply with food safety standards and regulatory requirements.

3. Regulations and Standards

·Countries and regions have corresponding regulations and standards regarding the use and safety of food-grade phospholipids.

·These regulations specify permitted usage levels, application scopes, and safety indicators.

·Producers and users of phospholipids must comply with these regulations to ensure product safety and legality.

4. Risk Assessment

·Conducting risk assessments is crucial to ensuring the safety of phospholipids.

·Risk assessments involve identifying potential hazards, evaluating their severity and likelihood, implementing preventive measures, and monitoring risks.

·By performing risk assessments, potential safety issues can be identified and addressed promptly, ensuring the safety and reliability of phospholipid products.

Food-grade phospholipids are sourced from a variety of materials, and their safety evaluation encompasses extraction and production processes, testing and certification, regulatory compliance, and risk assessment. Phospholipid producers and users must strictly follow relevant regulations and standards to ensure product safety and quality. Consumers, when purchasing and consuming foods containing phospholipids, should also pay attention to the source, production date, and expiration date to safeguard their health.

CN

CN