Customized hot aflatoxin adsorbent

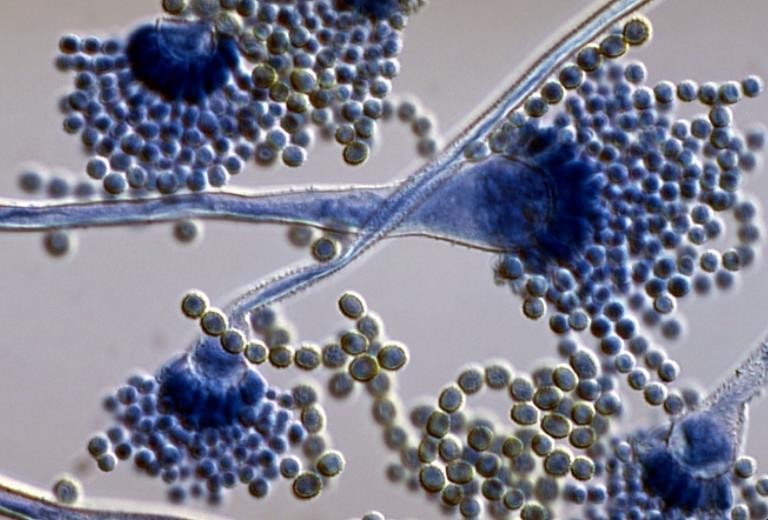

Time:2023-11-20Paying attention to the industry of aflatoxin adsorbent is crucial when customizing such products. Aflatoxins are toxic substances produced by certain molds, primarily Aspergillus flavus and Aspergillus parasiticus, and they can contaminate various agricultural commodities, including grains, nuts, and oilseeds.Aflatoxin contamination poses significant health risks to humans and animals, and the development of effective adsorbents is essential in minimizing these risks. There are key considerations when customizing aflatoxin adsorbents,ingcluding understanding aflatoxin characteristics,regulatory compliance,specific application requirements,adsorbent material selection,optimization of adsorption capacity,stability in various conditions,compatibility with feed and food products,dosage and application methods,cost considerations,research and development,safety considerations,ect.

Understanding Aflatoxin Characteristics:

Different aflatoxin types (e.g., B1, B2, G1, G2) may require different adsorption strategies. Understanding the characteristics of aflatoxins is crucial for designing an adsorbent that can effectively bind and remove these toxins.

Regulatory Compliance:

Complying with regulatory standards for aflatoxin levels in food and feed is essential.Ensure that the customized adsorbent meets or exceeds regulatory requirements set by relevant health authorities and agricultural agencies.

Specific Application Requirements:

Consider the specific application of the aflatoxin adsorbent.Different commodities and industries may have varying requirements in terms of adsorbent efficacy, dosage, and compatibility.

Adsorbent Material Selection:

Choose adsorbent materials that have a high affinity for aflatoxins.Commonly used adsorbents include activated carbon, clay minerals (e.g., bentonite), and certain binding agents.

Optimization of Adsorption Capacity:

Optimize the adsorption capacity of the customized adsorbent to ensure maximum efficiency in binding aflatoxins.This may involve adjusting the porosity, surface area, and other characteristics of the adsorbent material.

Stability in Various Conditions:

Aflatoxin contamination can occur in different environmental conditions.Ensure that the customized adsorbent remains stable and effective under a range of pH, temperature, and humidity conditions.

Compatibility with Feed and Food Products:

If the adsorbent is intended for use in the agricultural or food industry, ensure that it is compatible with the targeted commodities and does not negatively impact their quality or nutritional value.

Dosage and Application Methods:

Determine the optimal dosage of the aflatoxin adsorbent and the appropriate application methods.This may include incorporation into animal feed, food processing, or post-harvest treatments for crops.

Cost Considerations:

While aiming for efficacy, consider the cost-effectiveness of the customized adsorbent. Evaluate the economic feasibility of large-scale production and application in the intended industry.

Research and Development:

Stay informed about advancements in aflatoxin adsorption research and development. Emerging technologies and innovations may provide opportunities for improving the performance of adsorbents.

Safety Considerations:

Ensure that the aflatoxin adsorbent is safe for use in the intended applications and does not introduce any additional health risks.

Customizing aflatoxin adsorbents requires a multidisciplinary approach involving knowledge of chemistry, agriculture, food safety, and regulatory compliance.Collaboration with experts in these fields and conducting thorough testing and validation are essential steps in the development of effective and safe aflatoxin adsorbents.

CN

CN