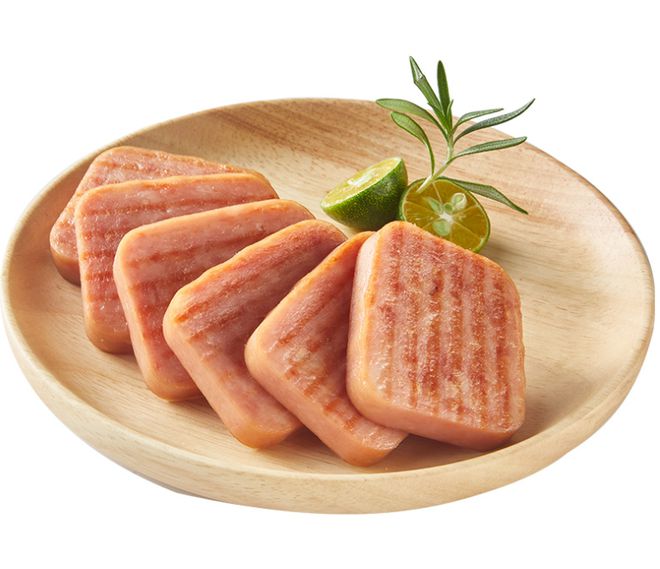

Supply High Purity Phosphatidylserine,Lunch Meat Production

Time:2024-09-14When using phosphatidylserine in the production of luncheon meat, the following aspects need to be considered:

1. Selecting the Appropriate Source and Quality of Phosphatidylserine

· Source Safety: Ensure that phosphatidylserine is derived from reliable, uncontaminated raw materials, such as the residual oil from natural soybeans. Avoid using raw materials that may contain heavy metals, pesticide residues, or other harmful substances.

· Quality Assurance: Choose high-purity, high-quality phosphatidylserine products to ensure their stability and effectiveness in luncheon meat.

2. Controlling the Dosage and Usage Method

· Dosage Control: Based on the formulation and process requirements of luncheon meat, control the amount of phosphatidylserine added. Generally, the recommended daily intake for general health purposes is around 200 mg. If there are special needs, the daily limit should not exceed 600 mg to avoid potential adverse effects from overconsumption.

· Usage Method: Mix phosphatidylserine evenly into the luncheon meat ingredients to ensure uniform distribution within the product, maximizing its efficacy.

3. Considering Interactions with Other Ingredients

· Compatibility: During the production of luncheon meat, phosphatidylserine may interact with other additives or ingredients. Therefore, thorough testing and evaluation should be conducted beforehand to ensure compatibility with other components.

· Stability: Pay attention to the stability of phosphatidylserine during the production and storage of luncheon meat, avoiding degradation or loss of effectiveness due to environmental factors such as temperature and humidity.

4. Focusing on Consumer Health and Safety

· Target Population: Be aware of the suitable and contraindicated populations for phosphatidylserine. For example, infants, people with liver or kidney impairments, and those with allergies should avoid consuming luncheon meat containing phosphatidylserine.

· Labeling: Clearly indicate the content of phosphatidylserine and relevant information on the packaging of the luncheon meat, allowing consumers to make informed decisions.

5. Complying with Relevant Laws and Regulations

· Food Safety Regulations: Strictly comply with national food safety laws and regulations during the production of luncheon meat to ensure the use of phosphatidylserine meets the relevant standards and requirements.

· Novel Food Management: According to the provisions of the "Regulations on the Management of Novel Foods," ensure that phosphatidylserine is legally used as a novel food ingredient in luncheon meat.

The use of phosphatidylserine in the production of luncheon meat requires a comprehensive consideration of multiple factors to ensure product quality, safety, and health benefits.

CN

CN